Questions and Answers on Rope Rescue Equipment

Raising and lowering loads during a technical rescue require

Beyond the techniques and gear, a successful rescue relies in large part on great teamwork. The complex maneuvers during a technical rescue (hauling loads, creating hoisting systems with lightweight pulleys, counterbalances…) require team members to work in perfect synchronization together.

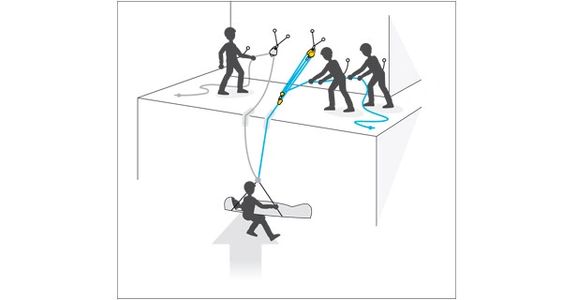

Examples of hauling with work rope and belay rope.

Team rescue techniques for hauling and lowering

All maneuvers must be done on two independent rope systems. These two systems can work in parallel (two haul lines) or separately (work rope and belay rope).

All hauling and positioning forces are concentrated on the work rope. The belay rope is set up and kept taut enough to hold the load in the event of anchor or work rope failure.

Advantages

- Quick and simple setup, only one mechanical-advantage system needed.

- Two different systems may be used, for example a mechanical haul system (winch...).

- Configuration suited to small work spaces.

Disadvantages

- If the work rope breaks, the clearance needed can be significant when the belay rope comes under load.

- Risk of developing slack in the belay rope by focusing too much on the primary system.

- Risk of neglecting the quality of the belay system setup. Warning: this system must be fully operational at all times.

- Risk of the rope path shifting and of unforeseen abrasion on the belay rope as it comes under load following a work rope failure.

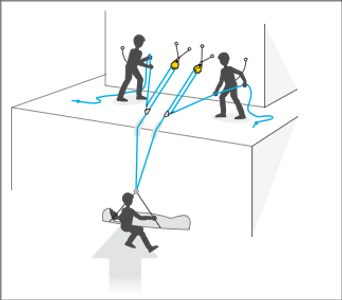

Examples of hauling with twin tensioned haul lines

The two ropes have the same function and work in parallel: each rope supports half the load.

Advantages

- With good coordination, it’s possible to haul a heavy load even with simple pulley systems.

- If one rope breaks, the other is already tensioned to hold the load, reducing the amount of clearance required.

- It is possible to manage a complex litter route if the rope paths are anticipated.

Disadvantages

- Load sharing between the two ropes is never perfect; sometimes one rope holds the entire load; good coordination of team members is required.

When should I retire my equipment?

Access Rescue Provides Inspection Services

Access Rescue Provides Inspection Services

A product must be retired when:

- It is over 10 years old and made of plastic or textiles

- It has been subjected to a major fall or load

- It fails to pass inspection

- Its reliability is in question

- Its entire history is not known (e.g. found or second-hand product)

- When it becomes obsolete due to changes in legislation, standards, technique or incompatibility with other equipment, etc.

Destroy retired equipment to prevent further use.

Access Rescue Provides Inspection Services

Access Rescue Provides Inspection Services

Access Rescue Provides Inspection Services

Legislative Compliance requires inspection and documentation of all PPE and Rescue Equipment. This must be completed by a Competent Inspector. We utilize our comprehensive PPE-management system to ensure, in part:

- All PPE meets Ministry of Labour Requirements for your Industry and Scope of Work.

- All PPE is in good-repair and operational within manufacturer's specifications, communiques and directives.

- All PPE is compatible with auxillary equipment being used for work.

- All inspections are complete and documented.

What is the lifetime of my Petzl equipment?

How can I find out the age of my Petzl PPE?

What is the lifetime of my Petzl equipment?

For plastic or textile products, the maximum lifetime is ten years from the date of manufacture (See: How can I find out the age of my Petzl PPE?.)

The lifespan of metal products is not limited.

Warning: An unusual event may require you to retire a product after only one use. This may involve the type and intensity of use, or the environment in which it is used: aggressive environments, sharps, extreme temperatures, chemicals...

What is PPE?

How can I find out the age of my Petzl PPE?

What is the lifetime of my Petzl equipment?

PPE is Personal Protective Equipment, equipment worn or carried by the user.

PPE is classified in three categories:

Category 1: minor hazards, light mechanical impacts, solar radiation

Category 2 : serious hazards

Category 3 : major or deadly hazards

PPE helps protect a person from deadly or serious health hazards. It includes all equipment designed for protection from long falls: rope clamps, descenders, harnesses, lanyards, webbing, slings, ropes, energy absorbers, carabiners, pulleys, swivels, rigging plates, ice axes, snow stakes and pitons. It excludes anchor points that are an integral part of a structure.

How can I find out the age of my Petzl PPE?

How can I find out the age of my Petzl PPE?

How can I find out the age of my Petzl PPE?

All our PPE products are identified by a serial number. This number may be marked in a number of ways: laser, engraving, label, etc. It allows us to identify our products. To find out the year of manufacture, refer to this detailed serial number in the following manner: Example for recent PPE: 09 365 AB 1 234

- 09 corresponds to the year of manufacture

- 365 corresponds to the day of manufacture in that year

- AB is the code of the person who inspected the product

- 1234 is the individual product number

How should I store my equipment?

What is the inspection process of PPE?

How can I find out the age of my Petzl PPE?

Clean and dry your equipment, if necessary. Store your equipment in a temperate, dry place protected from UV rays and chemicals.

What is the inspection process of PPE?

What is the inspection process of PPE?

What is the inspection process of PPE?

In addition to the inspection before each use, an in-depth inspection of your PPE must be carried out by a competent inspector. The frequency of the in-depth inspection must be governed by applicable legislation, and the type and intensity of use. Petzl recommends an inspection at least once every 12 months. To help maintain product traceability, do not remove any markings or labels.

How can I label or identify a sling?

What is the inspection process of PPE?

What is the inspection process of PPE?

The chemical make-up of markers, paints, adhesive tapes, and stickers may be incompatible with nylon or polyester. These chemicals can weaken the fibers and alter the structure and strength of textile products.

As a precaution, Petzl recommends using the identification label, or the end of the non-load bearing excess webbing, to mark a product.

A good choice of carabiner shape can increase ergonomics and security for certain uses

A carabiner is designed to be loaded on the major axis, with the gate closed and the sleeve locked.

Only the strength rating for the major axis with gate closed is suitable for the loads sustained by a carabiner in vertical activities. The shape of the carabiner frame has an influence on:

• major axis strength

• load distribution

• gate opening size, and capacity

• strength in certain positions

• ease of handling

Another less obvious effect is the balance of the carabiner itself: for example pear-shaped carabiners rotate more readily, which can result in poor positioning.

Pear-Shaped Carabiner

Wide-Opening Carabiner

Wide-Opening Carabiner

Another less obvious effect is the balance of the carabiner itself: for example pear-shaped carabiners rotate more readily, which can result in poor positioning.

Wide-Opening Carabiner

Wide-Opening Carabiner

Wide-Opening Carabiner

Wide opening facilitates attachment to anchors and cables.

Oval-Shaped Carabiner

Symmetric shape for even loading (devices with a large attachment hole, pulleys...).

D-Shaped Carabiner

Positioning of the load in the strongest axis, closest to the spine side of the frame. Suited to simple loads (connection of devices, attachment to the anchor...).

Pear-Shaped Carabiner

Wide-Opening Carabiner

Wide-Opening Carabiner

Remember that a pear-shaped carabiner may rotate more readily which can result in poor positioning.

Wide-Opening Carabiner

Wide-Opening Carabiner

Wide-Opening Carabiner

Remember that a wide opening facilitates attachment to anchors and cables.

O-Shaped Carabiner

O-Shaped Carabiner

O-Shaped Carabiner

Remember that an 0-shaped carabiner's symmetric shape facilitates even loading.

D-Shaped Carabiner

O-Shaped Carabiner

O-Shaped Carabiner

Remember that a D-shaped carabiner is suited to simple loads.

More About Carabiners

Rating of a Carabiner

All carabiners come with a kN, or kiloNewton rating engraved into the spine. If you have carabiners without a kN rating DO NOT use them for a life-load.

A kiloNewton is equal to about 225 lbs., which is a force of gravity rating, not static weight or mass. If you remember back to algebra class, force is equal to mass times acceleration.

Everything you use for technical rope rescue, rope, webbing, carabiners, anchors and protection is designed to absorb the force (or shock) that’s generated by a fall.

All this equipment has a certain rating of force it can withstand, and that rating is typically referred to as a kN rating.

That rating doesn’t take into account wear and tear on your gear, so always check everything before use, and replace anything with excessive wear.

Strength

We mentioned previously that the greatest strength of a carabiner is in its spine, and is why kN ratings typically offer two different strength ratings. One if the load is distributed along the spine, and another if the load somehow gets distributed across the gate.

Obviously, distributing a load on the gate of the carabiner isn’t good, and this is evident by the kN rating which will typically be 1/3 of what the spine rating is. For example, the manually locking carabiner in our photos is rated at kN 27 along the spine, and kN 8 to 9 across the gate.

If you really look at the construction of carabiners you’ll see why they’re rated less along this axis. All that’s holding the gate to the carabiner is a pin where the spring portion of the gate is located.

As you can imagine, an aluminum pin of that size can not offer a comparable load rating vs. the spine of the entire carabiner.

Don’t get us wrong, 8 to 9 kN is still almost 2000 lbs. of force that the pin can take, but wouldn’t you feel safer knowing you were protected by 27 kN (6000+ lbs.).

The Minimum Breaking Strength (MBS) is a statistically derived value but what does it mean?

The Minimum Breaking Strength (MBS) is a statistically derived value and is poorly understood.

If 100 carabiners are submitted for destructive testing then the measured strengths will vary considerably. Inconsistencies in the manufacturing process may result in larger variations. The batch test results can be plotted on a histogram showing the probability of breaking at particular strengths and this curve should approximate a “normal distribution” or “bell curve”.

The width of the curve is characterised by the “standard deviation” or σ (sigma). 3σ for a normal distribution indicates that 99.7% of samples should lie within the range of (mean – 3σ) to (mean + 3σ). Smaller values for σ indicate that samples are more likely to be close to the average, or mean value.

Many carabiner manufacturers state that they use “3-sigma” to determine their MBS values. This means that the MBS is actually the mean breaking strength less 3 times the standard deviation (3σ). Therefore, 99.7% of test samples should break above the MBS.

Maximum acceptable load in normal use

Material behaviour under load is normally characterised by stress vs strain curves. Two terms that are useful in describing this behaviour are Elastic and Plastic Deformation. When a carabiner is stressed by applying tension along the spine it will begin to ‘stretch’ at a relatively low force. If the carabiner returns to its ‘normal’ shape once the stress is removed then we can describe this stretching as ‘Elastic Deformation’. As the stress becomes more significant this ‘stretching’ may enter an irreversible range known as ‘Plastic Deformation’.

So, carabiners should not fail below their MBS however they will undergo irreversible deformation before reaching this point. Also, it is perfectly reasonable to expect that repeated heavy loading will fatigue the material and result in failure below the MBS.

The question that may come out of this discussion is “How much can we load a carabiner without resulting in plastic deformation or significant fatigue?” Some manufacturers address this explicitly in documentation stating that connector loading should never exceed 1/4 of the MBS.

Design Factor

The Design Factor (DF) is specified by a designer or manufacturer and this defines the factor applied to the MBS to determine maximum load acceptable load for a component.

Safety Factor

Safety Factor (SF) is generally defined by industry rather than manufacturer. It may be significantly different to Design Factor. For example, a particular connector may have an MBS of 50kN, a manufacturer specified DF of 4, but an industry specified SF of 10 when used for a particular application.

WLL

Working Load Limit (WLL) is a term used by manufacturers to indicate the maximum force that should be applied to a carabiner in normal use, regardless of industry. The ratio of MBS to WLL is referred to as the Design Factor (DF). Many carabiner manufacturers specify a DF of 4 which implies a WLL of a quarter of the MBS. Manufacturers state the WLL to ensure that the carabiner is not subjected to significant fatigue and remains in the range of normal elastic deformation.

SWL

Safe Working Load (SWL) is typically determined by dividing the MBS of a carabiner by the Safety Factor (SF) required for a particular use. As stated above it possible that an entertainment rigger may calculate a different SWL for a particular use of a carabiner than the value determined by a rescue technician.

Example

A particular steel carabiner has a 3-sigma rated long-axis MBS of 50kN. The manufacture has specified a DF of 4 for this connector, regardless of use.

This carabiner has a WLL of 12.5kN and this value should never be exceeded in normal use – regardless of industry or application. If this value is exceeded it should not fail below the MBS however it should then be removed from service and destroyed.

An entertainment rigger, working in a certain country is required by the industry code-of-practice to use a SF of 10 for flying performers and thus, determines the SWL of this carabiner is 50kn/10 = 5kN.

A rescue technician in another country is supposed to apply a SF of 5 to hardware and thus determines a SWL of 50kn/5 = 10kN for an identical connector.

Access Rescue Canada

3317-C Mainway Drive, Burlington, ON L7M 1A6

We're a registered Training Corporation with Industry Canada and an active member of the National Fire Protection Association

Copyright © 2003-2025 Access Rescue Canada, Inc.